- Shandong Yifu Steel Sheet Co., Ltd.

- yifusteel@gmail.com

- 0086-0543-8910777

Main Products

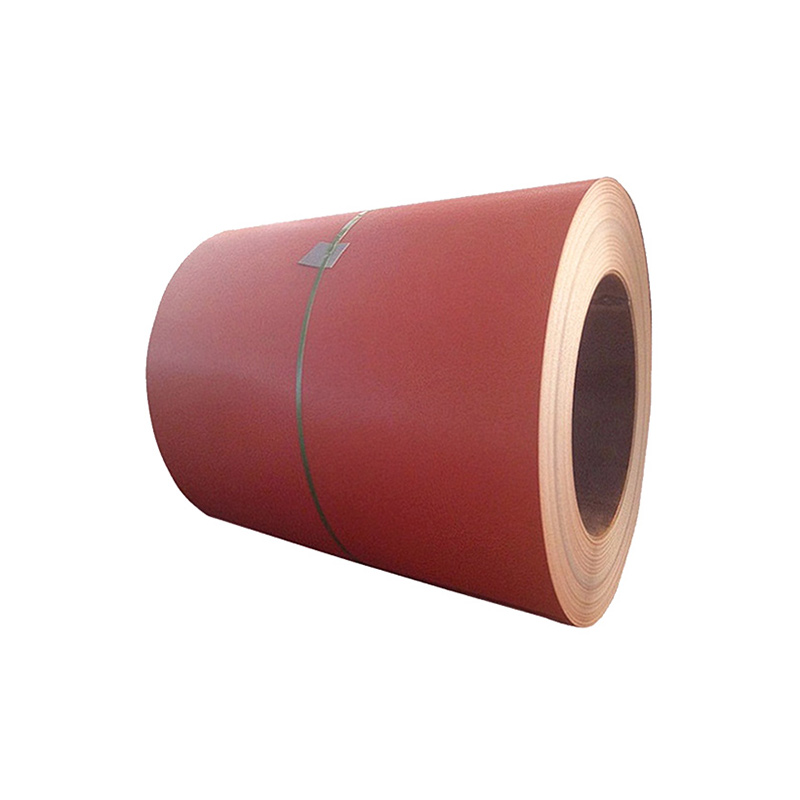

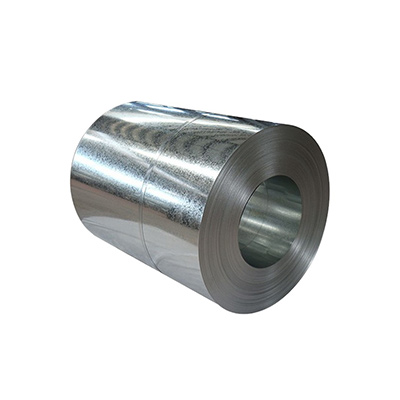

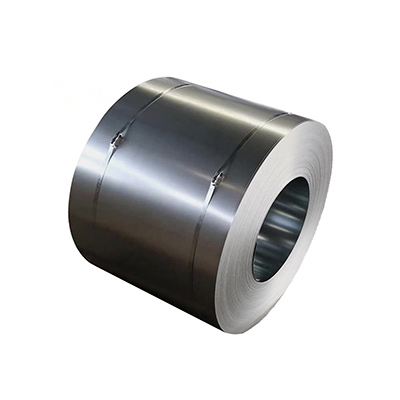

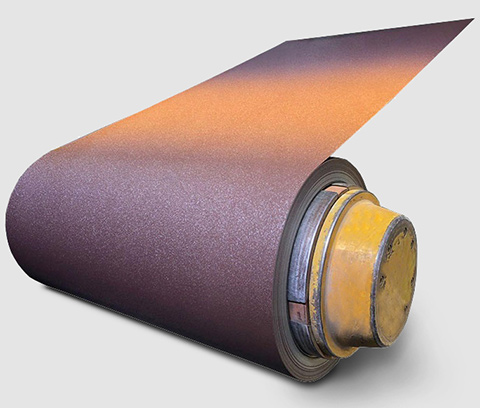

Prepainted galvanized steel coil(PPGI), galvanized steel coil(GI), Galvalume steel coil(GL), Aluminum, Roof sheet. Our own factory has been built 2 Galvanized production lines (0.11MM-2.0mm *33mm-1250mm), 3 prepainted gavanized production lines (0.11MM-0.8MM*33-1250MM)and 15 corrugated steel sheet machines (0.15MM-0.8MM*750MM-1100MM).

Areas of Work

Our products cover more than 55 countries and regions in Central Asia and the Middle East, Eastern Europe, West Africa, East Africa, South America, etc.

Our Advantages

The company is willing to "high-quality products, perfect service" sincerely look forward to working with you to create brilliant!

-

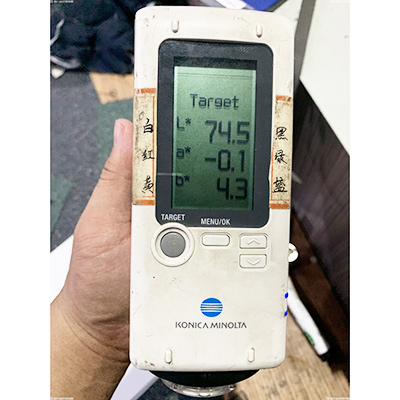

Strict Quality Control

Strict quality control in production line and inspection labs, tested by third party.

-

High Production Efficiency

Professional workers, technicians, R&D personnel, and a good life from that attitude.

-

Safe Packaging And Loading

Adopt 5 bands *5 bands High-grade export packaging.

-

Competitive Price

Factory direct sales, Competitive price and one-stop service.

about us

Shandong Yifu Steel Sheet Co., Ltd. was founded in 2009, focusing on building a high-end steel coil brand – YIFUSTEEL. It is one of the top modern enterprise integrating the R&D, manufacture and trade of cold-rolled coil, galvanized steel coil(GI), and color-coated steel coil (PPGI).The company is located in the North Gate of Shandong Province, Boxing Dianzi Industrial Park.

-

55 Export Country

Domestic and foreign markets -

300000T Capacity per Month

2 galvanized steel lines and 3 color-coated steel lines -

500+ Staff

R&D, technology, workers, administration -

15+ Industry Experience

Specializing in Steel business

Latest News

-

Newslearn more

Newslearn moreAbout color coated steel coil /prepainted steel coil structure

The failure process of color-coated steel plate is shown in the figure above. Coating failure, coating failure and perforation of steel plate are the key corrosion processes. Therefore, increasing the thickness of coating and using weathering and corrosion resistant coating are the most effective means to prevent corrosion failure of color coated steel plate. -

Newslearn more

Newslearn moreFactors affecting the use of PPGI steel coil

The anticorrosive effect of building color coating products is the combination of coating, pretreatment film and coating (primer, top paint and back paint), which directly affects its service life. From the anticorrosion mechanism of color coating, organic coating is a kind of isolation material, which isolates the substrate from the corrosive medium to achieve the purpose of anticorrosion. -

Newslearn more

Newslearn moreThe use environment of color-coated steel coil

Sunlight is electromagnetic wave, according to the energy and frequency of the level is divided into gamma rays, X-rays, ultraviolet, visible light, infrared, microwave and radio waves. The ULTRAVIOLET spectrum (UV) belongs to the high frequency radiation, which is more destructive than the low energy spectrum.